Address:

Block D8-D14, Seethawaka Export Processing Zone,

Avissawella,

Sri Lanka.

Telephone:

+94 (36) 4 279 500

Fax

+94 (36) 4 279 595

Email:

info@teejay.com

Web:

http://www.teejay.com/

Q: What lessons has Teejay Lanka learned from the COVID-19 crisis?

A: We view the crisis as two waves – the first in March 2020 brought everything to a halt as the company looked to con- clude a successful year. At this point, we focussed on our teams’ safety and meet- ing commitments made to customers by recommencing operations.

Operations commenced in the first week of April with protocols based on government guidelines.

We gathered momentum and were at full capacity when the second wave emerged. However, we were prepared and focussed on maintaining our opera- tional momentum and keeping the plants open while isolating positive patients, and caring for them and their families.

To this end, we established a special pay scheme to ensure that members were not financially impacted while quaran- tined. This was achieved through Teejay Lanka’s resolute leadership and the sup- port of the competent teams who contin- ue to assist us in facing the unprecedent- ed challenge of COVID-19.

Q: How can business overcome the impact of the pandemic?

A: Businesses need to be resilient to weather this unprecedented crisis. Flexibility is necessary but if companies are structured with appropriate protocols from their inception, external influences will not matter.

Despite COVID-19 or any other challenge, business will continue. Sri Lankan companies serve as great examples of resilience – we’ve survived despite experiencing years of ter- rorism, a tsunami and the Easter Sunday attacks in 2019. Our businesses continue to survive because of the strategies in place.

Q: Do organisational performance and sustainability go hand in hand?

A: We continuously re-engineer our prod- ucts to improve resource efficiency and min- imise waste by improving product perfor- mance, overhauling conventional construc- tion practices. For example, our Blended Hydraulic Cements have a lower carbon footprint to meet the highest environmental standards.

Tokyo Cement Group played a role in pio- neering renewable biomass energy generation in Sri Lanka with a present capacity of 24 MW. The two biomass power plants in Trincomalee make our local produc- tion process entirely energy independent while the Mahiyangana dendro power plant contributes to the national grid.

Mangrove reforestation and coral reef rehabilitation are among the conservation initiatives we’re engaged in. Our tree planting programme grows native trees to support national reforestation efforts. Each year, our factories plant more than 20,000 trees across the island together with multiple partner organisations.

Q: Where do you stand on the debate about working from home (WFH)?

A: Being a manufacturing entity, most of our workers are on the shop floor so they have no option but to come to work. However, the rest of the team has the option to work from home. This serves two purposes: keeping them safe from the virus and ensuring business continuity. And this has helped us prevent outsiders from entering the plant for fear of exposure.

WFH has pros and cons. As an entity that is 50- 60 kilometres away from Colombo, it helps with commute times. In the present scenario, people are at home with their families in case there are issues. Moreover, they wake up feeling rested and begin working – it is ‘quality mind time’ for work.

However, WFH can also dilute concentration and employees may not have suitable worksta- tions to help with this, which can become stressful. To overcome this, we’ve provided WFH staff with basic guidelines to adhere to along with the necessary facilities.

We believe that WFH will be the future in the long haul. The Western world has already embraced it and so will we in time.

Q: What measures were taken to sustain the business in the past 12 months?

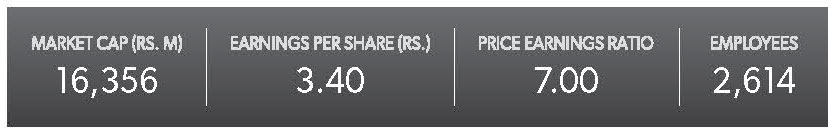

A: Teejay Lanka recorded US$ 100 million in revenue in 14 years; and in the last six years, it earned 200 million dollars. We hope to increase this to US$ 300 million in the next few years.

The past few months have been about modernisation, and strengthening our innovation and development, while enhancing our talent base and partnering with an array of new international brands to bolster the business.

Q: How has innovation and technology impacted the apparel industry?

A: At this time, innovation is vital in any industry – ‘Industry 4.0’ can revolutionise entire businesses, which is no different in the textile industry.

We’re excited to dive into the field of smart textiles and eager to master it as this is the high end of the industry, which deals with innovation.

Q: Could you outline Teejay Lanka’s plans for the future?

A: We’re hoping to move up the value chain towards more syn- thetic-based products, which we began working on about four years ago. As of now, our plan is for more substantial growth with present expansion plans, as well as to bring new business into the company with better innovation and research.